How to Efficiently Load a 40 ft Container for Shipping?

Loading a 40 ft container efficiently is crucial for successful shipping. Maximizing space can save costs and time. Each inch matters when packing a container, as wasted space can lead to losses.

Proper planning plays a significant role. Measure items carefully and create a loading plan. Ensure items are stacked securely to prevent damage during transit. Remember, fragile items require extra attention.

Effective loading is not just about fitting everything in. It's about organization and accessibility too. Consider the sequence of unloading at the destination. Sometimes, a well-packed container might still pose challenges at arrival. Reflect on past experiences; learn from previous mistakes.

Understanding the Dimensions and Weight Limits of a 40 ft Container

Understanding the dimensions and weight limits of a 40 ft container is crucial for efficient shipping. A standard 40 ft container typically has an interior length of 12.03 meters and a height of 2.39 meters. The width remains constant at 2.34 meters. This provides about 67.7 cubic meters of volume, enabling the shipping of a significant amount of goods.

When considering weight, most 40 ft containers have a maximum gross weight limit of around 30,480 kg (67,200 lbs). It's essential to calculate the total weight of the cargo being loaded to avoid exceeding this limit. Overloading can cause damage to the container and affect transport safety. A recent industry report emphasized that around 5% of shipping mishaps relate directly to weight miscalculations, leading to costly delays.

Packing efficiently is as significant as adhering to dimensions and weight. Items should be stowed strategically to maximize space and maintain balance. Use padding for delicate goods, but be mindful not to waste valuable room. Ignoring these details may result in wasted cargo space. Challenges often arise in achieving the perfect balance of weight and volume. Each shipment requires careful planning and a reflective approach to enhance shipping efficiency.

Essential Packing Materials and Equipment for Container Loading

When loading a 40 ft container, the right packing materials and equipment play a crucial role. Many industry reports suggest that improper loading can lead to cargo damage, costing companies up to $150 billion annually. Essential packing materials include cardboard boxes, stretch film, and wooden pallets. Cardboard boxes should be durable, as they help distribute weight evenly. Stretch film seals the cargo, preventing movement.

Using the right equipment is equally important. A pallet jack or forklift can streamline the loading process significantly. According to studies, the use of proper equipment reduces loading time by 30%. However, it is vital to double-check that all tools are functioning correctly. Load locks and straps are also necessary to secure items in place. An unsecured load increases the risk of shifting.

Reflecting on the experience, it’s clear that even minor mistakes in packing can lead to costly repercussions. Calculating space efficiently is an ongoing challenge. Packing with a clear strategy can mean the difference between a smooth shipping process and a logistical nightmare.

Best Practices for Arranging and Securing Cargo Inside the Container

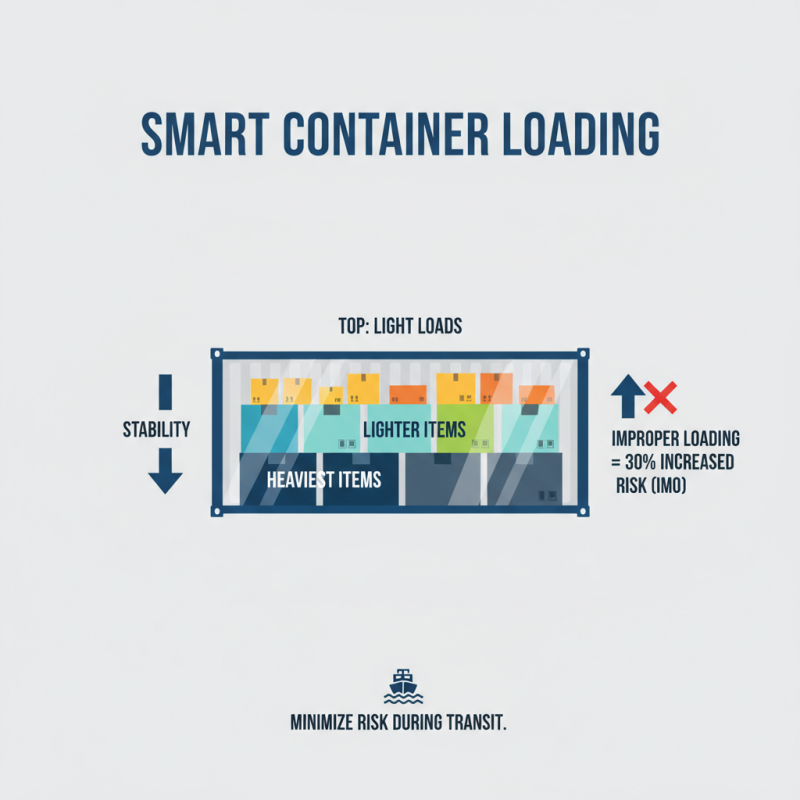

When loading a 40 ft container, arranging and securing cargo is crucial. Proper weight distribution can minimize risks during transit. It is recommended that the heaviest items should be placed on the bottom, with lighter items on top. This technique helps in maintaining stability. According to the International Maritime Organization, improper loading can lead to a 30% increase in the likelihood of cargo loss or damage.

Using dunnage, like wood or air bags, ensures that items do not shift. Pack fragile cargo closely to prevent movement. A study by the Container Owners Association states that nearly 40% of container damage is due to inadequate securing. It’s vital to utilize all available space, but overpacking can lead to complications. Leaving some space for air circulation might be counterintuitive, but it helps reduce condensation and damage.

Keep an eye on loading limits. Overloading a container by just 10% can lead to fines and increased transport risks. Visual checks are essential to spot potential issues before sealing the container. Regular training on loading practices for staff is also beneficial. It may seem redundant, but well-trained teams often yield better results. These reflective practices are necessary to refine the process continuously.

Strategies for Maximizing Space Utilization in Shipping Containers

When loading a 40 ft container, space is often limited. Maximizing space efficiency is crucial. Utilizing every inch can save costs and improve shipping outcomes. It’s not just about cramming items in. The arrangement matters greatly.

Start by assessing the items you need to load. Heavy items should go on the bottom. Lightweight, fragile items can be on top. This keeps weight balanced. Use the height of the container. Stack items strategically to create vertical layers. Tips: Use pallets to facilitate stacking. Secure each load to prevent movement during transport.

Consider the shape of your items. Oddly shaped products can create gaps. Fill these with smaller items or packing materials. This method reduces wasted space. Don’t underestimate planning. Draft a layout before loading. Sometimes, plans don't work out perfectly. Be adaptative. It's okay to rethink your strategy on the spot. Finding the best arrangement can take a few tries but leads to better shipping efficiency.

How to Efficiently Load a 40 ft Container for Shipping? - Strategies for Maximizing Space Utilization in Shipping Containers

| Item | Dimensions (cm) | Weight (kg) | Volume (m³) | Loading Strategy |

|---|---|---|---|---|

| Pallets | 120 x 100 x 15 | 200 | 0.18 | Stack vertically |

| Bags | 50 x 50 x 90 | 25 | 0.23 | Fill gaps |

| Boxes | 60 x 40 x 40 | 15 | 0.096 | Layered packing |

| Drums | 58 x 58 x 90 | 220 | 0.25 | Secure tightly |

| Furniture | Variable | 50 | 1.2 | Disassemble if possible |

Common Mistakes to Avoid When Loading a 40 ft Shipping Container

Loading a 40 ft container efficiently is essential for maximizing space and minimizing costs. One common mistake is failing to measure the dimensions of your products. According to a logistics study, 30% of shipping delays are due to improper measurements. Without accurate dimensions, you risk leaving unused spaces or, worse, overloading the container.

Another mistake is neglecting to balance the load. An uneven load can shift during transit, potentially damaging the cargo. The industry recommends distributing weight evenly across the container. This also helps maintain the container's structural integrity. Aim for the center of gravity to be low for added stability.

Tip: Use dunnage to fill empty spaces. This prevents items from moving around and reduces the risk of damage. Also, always secure the cargo tightly with straps.

Finally, consider palletization. It simplifies loading and unloading, ensuring that every inch of space is used wisely. However, over-packing can lead to issues. Too many items can cause stress beyond the container's limits. So, it's key to strike a balance in your packing strategy.

Common Mistakes to Avoid When Loading a 40 ft Shipping Container

Related Posts

-

Maximizing Space: Innovative Uses for Your 20 ft Shipping Container You Haven't Considered

-

Maximize Your Space with a 20 ft Storage Container for Home and Business Solutions

-

How to Choose the Best Steel Shipping Containers for Your Needs

-

Exploring the Versatility of 40ft Containers in Modern Logistics Solutions

-

How to Choose the Right Shipping Containers for Your Needs?

-

10 Essential Tips for Finding Discount Shipping Containers Online?